We supply ebb and flow system products for greenhouse facility projects both domestically and internationally, mainly used for cultivating the Phalaenopsis, various orchids, other potted flowers and plants, as well as organic vegetables.

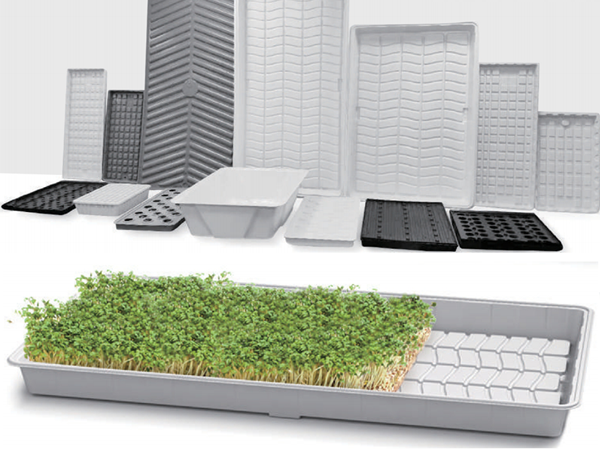

JY ebb and flow table is a unique cultivation table design, also known as bottom irrigation cultivation table, this design combines efficient irrigation techniques with the convenience of moving tables, achieving stability of the cultivation table through columns and support structures. And its unique flood trays, made of molded impermeable ABS, provides an ideal growth environment for crops. During the irrigation process, clear water or nutrient solution is injected into the seedling tray, and after a period of retention, the crops absorb the required water through the drainage holes at the bottom of the pot by capillary action. Afterwards, the irrigation water can be discharged from the cultivation table for reuse, or directly discharged into the local sewage pipeline, achieving efficient irrigation of water and fertilizer integration.

The assembly and installation steps of ebb and flow system are as follows:

1. Material preparation: The main components of the ebb and flow table (also called seedbed), flood trays, aluminum alloy frame, roller tube, handwheel, and bracket.

2. Assembly steps:

Install the handwheel onto the roller tube.

Lay the flood trays.

By rotating the ebb and flow table handwheel, the roller tube is driven to roll left and right, thereby the flood trays can move left and right by about 60 cm12.

3. Installation steps:

Lay out the lines inside the planting greenhouse and fix the seedbed base to the hardened road surface with expansion bolts.

Fix the seedbed legs and base with hot-dip galvanized bolts and perform leveling and fine-tuning.

Install the seedbed roller tube, crossbeam, and anti overturning card. Note that the spacing between the crossbeams is generally 50 or 65 centimeters, and the distance between the seedbed legs is generally 2.3 meters.

English

English