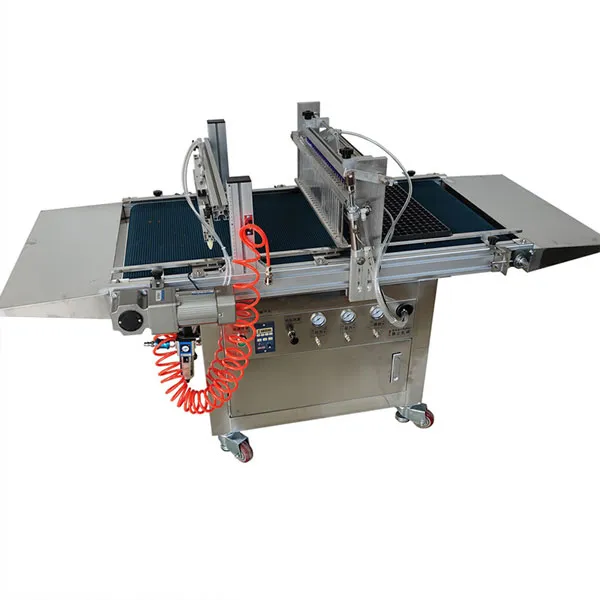

Specifications of Tray Seeder

Product | Tray Seeder |

Designs | The tray seeder is an automatic machine include the continuous processes of soil filling, hole punching, seeding, and soil covering. |

Other data | This automatic tray seeder equipment can shorten the seedling cycle (saving 5-10 days compared to traditional seedling cultivation), and more efficient seedling work with handling 380-680 trays per hour. |

Charatistics and Performance | * The automatic tray seeder have the features of efficiency, precision, and automation. * This tray seeder equipment significantly improves seedling efficiency. * The tray seeder uses a microcomputer control system, with a seeding accuracy rate of over 98%, ensuring uniform seedling emergence. * Using this automatic seeder also saves labor, each machine can replace about 10 workers. * And It is equipped with a touchscreen PLC control panel, allowing parameter storage and retrieval, making operation simple and intelligent. * The seedling tray seeder comes with a variety of suction nozzle sizes that can be quickly replaced to accommodate seeds of different shapes and varieties, and is compatible with standard trays. |

Application | The automatic tray seeder is an agricultural machinery device used for sowing seedling trays for vegetable and flowers. It is applied in seedling cultivation of the modern greenhouses and farm. |

How to Operate an Automatic Tray Seeder?

The operation process of the automatic tray seeder mainly includes equipment debugging, parameter setting, seed processing, seeding operation, and subsequent management.

1. Equipment Debugging and Parameter Setting

Connect the power supply (220V) and the air pump, press the air pump interface, and then start the power button. Select the corresponding mode on the display screen according to the type of tray being used, and adjust the tray size (e.g., 54×28cm national standard tray) and seeding parameters (single-row/double-row/alternate-row working mode).

2. Seed Processing and Suction Head Matching

Clean the seed impurities and choose a matching suction head (needle). Test whether the suction head can accurately pick up a single seed (replace if the needle is too small, adjust if too large).

Install the suction head and attach the rubber sleeve to prevent clogging or seed displacement.

3. Seeding Process

Place the tray with prepared substrate in position, close to the baffle.

Move the machine head above the tray, press down the operation handle to complete suction, tray pressing, and seeding.

After seeding, cover with soil and adjust the seeding depth to prevent the needle from penetrating too deeply into the substrate.

4. Application and Precautions

Applicable seeds with a diameter of 1-10mm (such as peppers, tomatoes), flowers, tobacco, etc. Tray holes support 50-200 cells.

And safety tips: Ensure that the suction head matches the seed during operation to avoid clogging or uneven seeding.

English

English